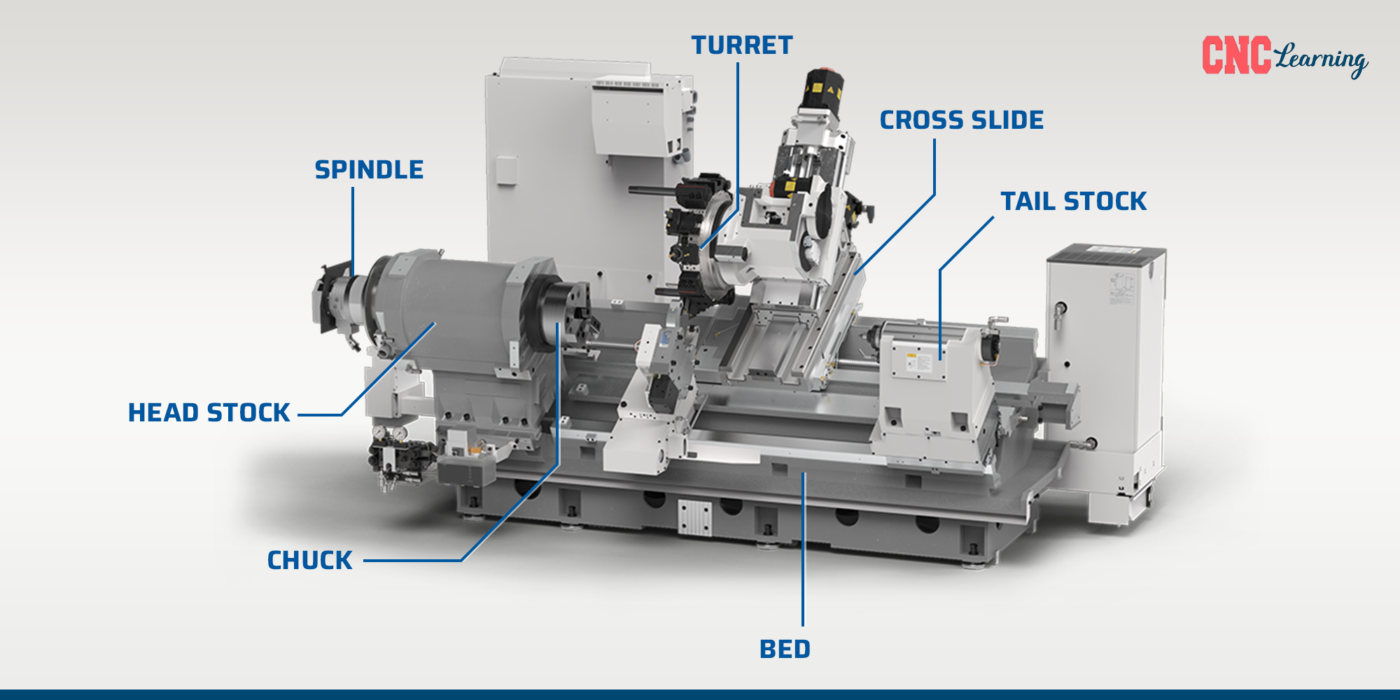

Turning centers are important machines in modern manufacturing. They perform turning operations with high precision and efficiency. Understanding the main parts of a turning center helps operators and engineers use the machine more effectively.

Here are the key components and their roles:

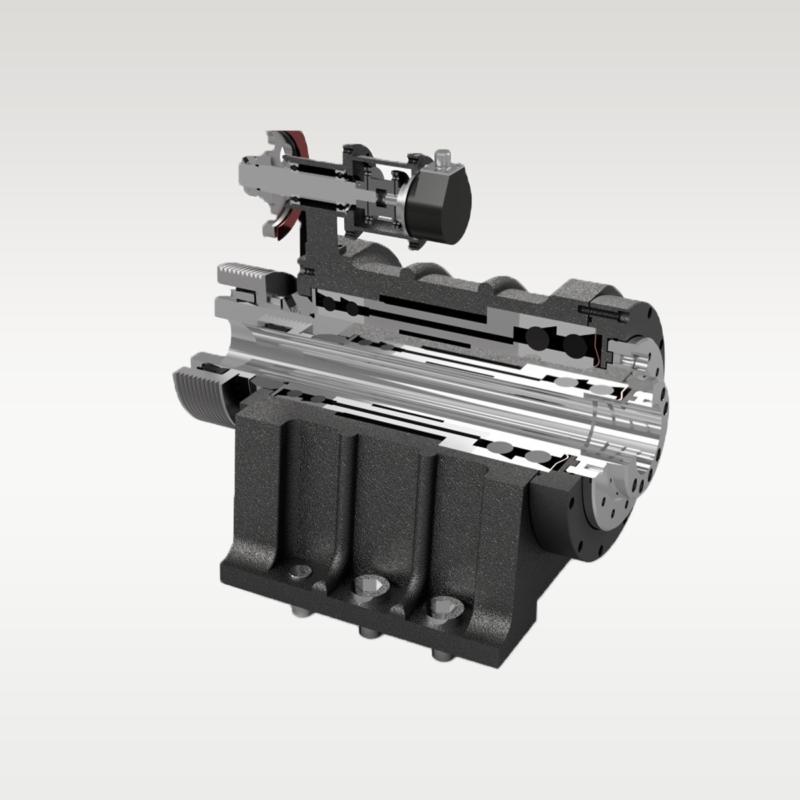

Head Stock

The headstock holds the main spindle and motor. It provides the rotation needed to turn the workpiece. The spindle often has a chuck or collet to grip the part securely. Headstocks can be gear-driven, belt-driven, or direct-drive, depending on speed and torque needs.

Tailstock

The tailstock is placed opposite the headstock. It supports the other end of the workpiece. This makes long or thin parts more stable during machining. The tailstock can slide along the bed, and its quill can be adjusted for depth.

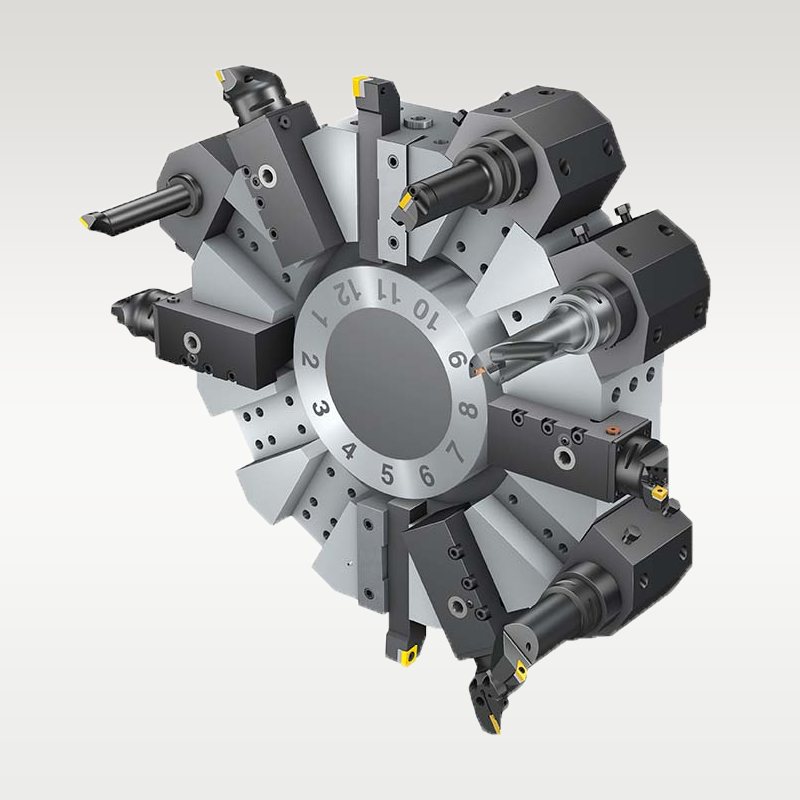

Tool Turret

The tool turret holds several cutting tools. It rotates to bring the correct tool into position. This allows quick tool changes and smooth machining. Some turrets also have powered tools for drilling or milling, in addition to turning.

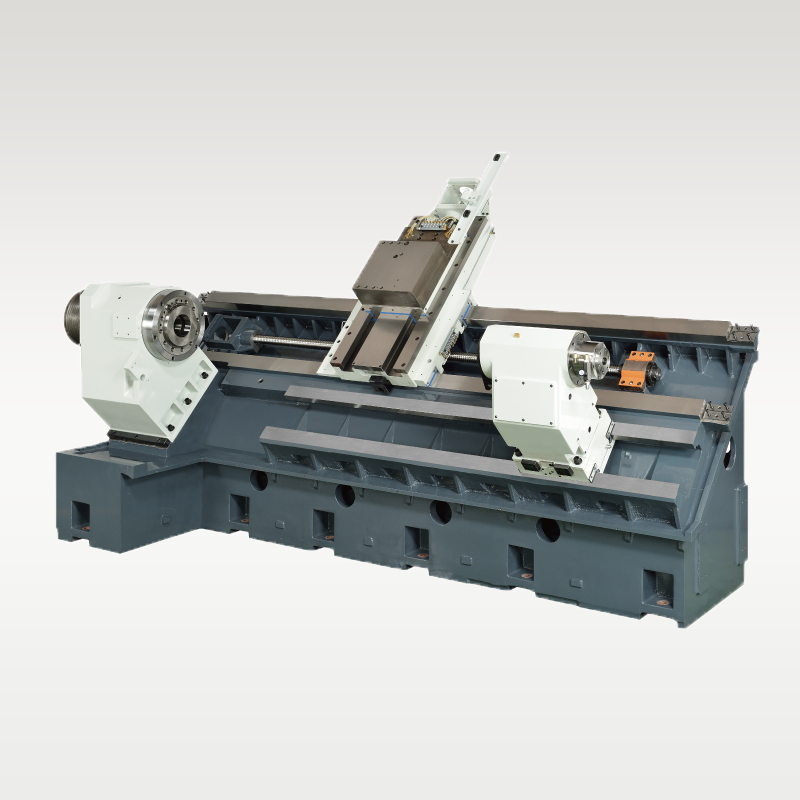

Bed

The bed is the base of the turning center. It supports the main components and keeps the machine rigid. A solid bed reduces vibrations and improves accuracy. Most beds are made from cast iron or steel. They also have guideways for the carriage and cross-slide.

Carriage

The carriage moves along the bed. It holds the cross-slide and tool post. This lets the cutting tool move along the length of the workpiece. Operators can control the depth of cut and feed rate with fine adjustments.

Cross-Slide

The cross-slide sits on the carriage. It moves the tool side to side, across the bed. This movement makes facing and turning operations possible. Cross-slides can be moved by handwheels or CNC control.

Spindle

The spindle is part of the headstock. It rotates the workpiece during cutting. The spindle speed can be changed to match the material or tool. Different machines offer spindles with varying power and precision.

Chuck

The chuck is attached to the spindle. It clamps the workpiece tightly in place. Three-jaw chucks are common for speed, while four-jaw chucks allow higher accuracy. Some machines use hydraulic or pneumatic chucks for faster operation.

Control Panel

The control panel is where the operator runs the machine. It has buttons, knobs, and a display screen. On CNC machines, the panel allows programming and automatic control. This makes machining faster and more consistent.

Coolant System

The coolant system delivers fluid to the cutting area. This reduces heat, lowers tool wear, and improves the finish. The system usually includes a pump, tank, and nozzles.

Chips and Waste Collection System

Turning produces chips and waste. The chip collection system removes them from the work area. This keeps the machine clean and prevents damage. Common systems include conveyors, augers, and vacuums.

Conclusion

Turning centers are made up of many parts, and each plays an important role. By learning about the headstock, tailstock, turret, spindle, and other components, operators can improve accuracy and efficiency.

Learn more about Canned Cycle

1. General CNC Machining Overview

-

Understanding CNC Machining – ThomasNet gives a solid introduction to CNC processes, terminology, and applications Thomasnet.

-

CNC Machining 101: A Comprehensive Guide – Autodesk explains core CNC concepts, benefits, and workflows in an easy-to-digest manner Autodesk+1.