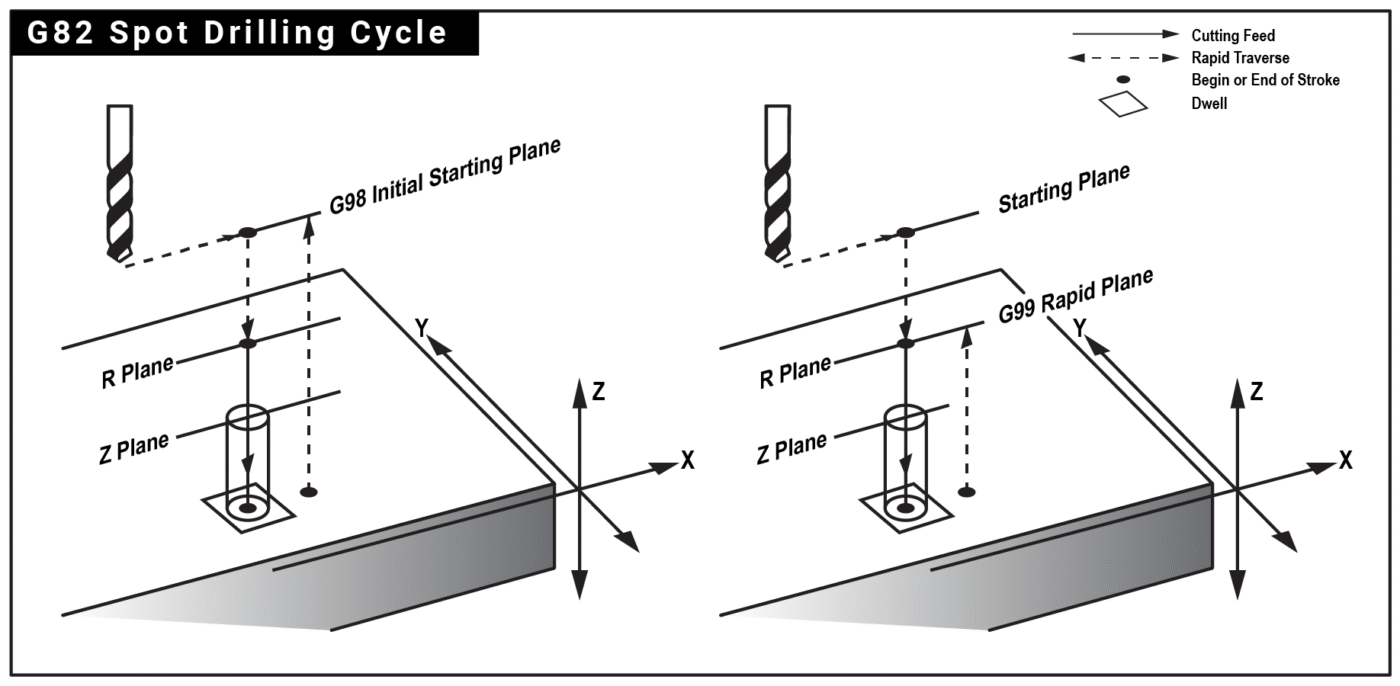

What the G82 Cycle Does

G82 is a drilling cycle similar to G81, but with an added dwell time at the bottom of the hole. After feeding down to the programmed depth (Z), the tool pauses for the specified time (P value) before retracting. This dwell improves hole accuracy, helps create a cleaner bottom surface, and is commonly used for countersinking and counterboring operations.

Syntax (Fanuc-Style)

G98/G99 G82 X__ Y__ Z__ R__ P__ F__

Parameters

-

X, Y – Hole position.

-

Z – Final hole depth.

-

R – Clearance plane (start of drilling motion).

-

P – Dwell time at bottom (milliseconds on most Fanuc controls; some older controls use seconds).

-

F – Feedrate.

-

G98 – Retract to initial plane.

-

G99 – Retract to R-plane.

Difference vs. G81: The only extra parameter is P (dwell). The cycle motion is identical otherwise.

Motion Sequence

-

Rapid to R-plane.

-

Feed to Z-depth.

-

Pause (dwell) for programmed P time.

-

Retract: either to R-plane (G99) or initial plane (G98).

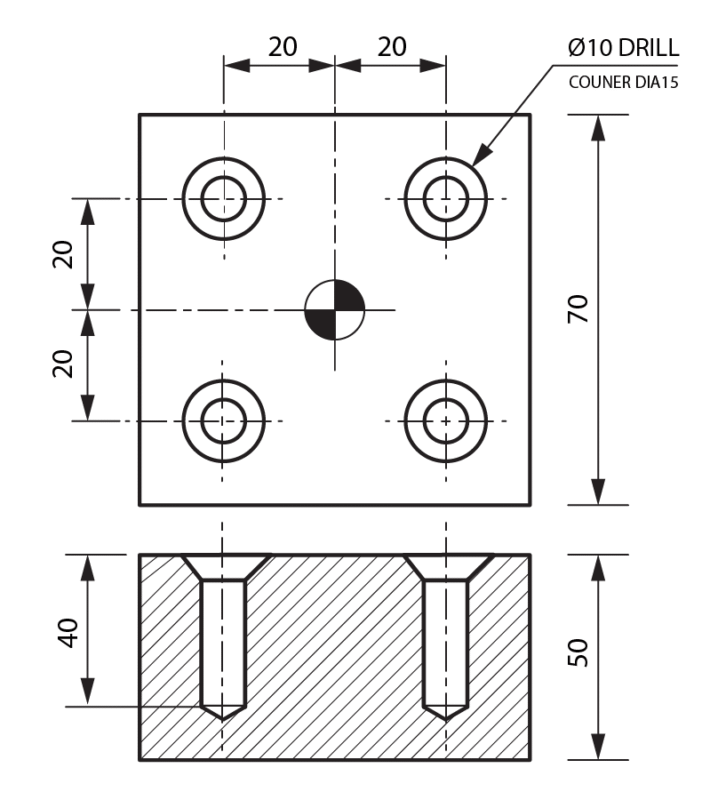

Example 1: Countersinking Holes

In this example:

- The drill rapids to R2.0, feeds to Z-7.5, then dwells 500 ms (0.5 sec) before retracting.

- The dwell ensures a smooth countersink bottom.

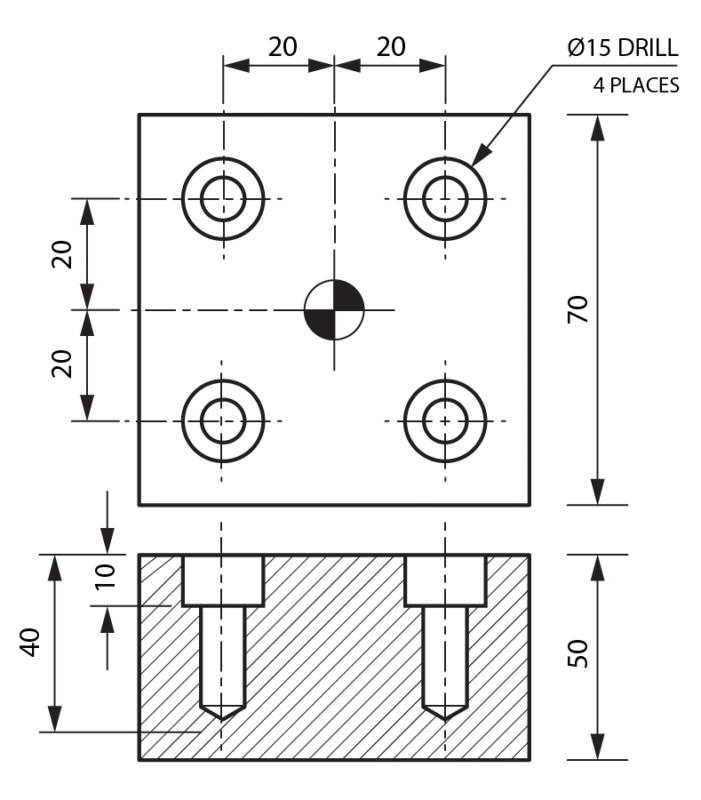

Example 2: Counterboring With Higher Retract

Feeds, Speeds & Dwell Tips

-

Dwell (P): Start with 300–500 ms for countersinks. Increase for larger tools or harder materials.

-

Feedrate: Use recommended drilling/countersinking feeds—too slow may cause chatter, too fast can damage edges.

-

Coolant: Strongly recommended, as the tool remains cutting during dwell.

-

Chip Control: G82 is not ideal for deep holes—use G83 instead.

When to Use G82

-

Countersinking.

-

Counterboring.

-

When a flat-bottom finish is required.

-

For precision holes needing consistent depth.

When Not to Use G82

-

Deep-hole drilling (use G83).

-

Tapping/threading (use G84).

-

Shallow, quick holes without dwell (use G81).

Common Mistakes & How to Avoid Them

-

Forgetting P: Without a dwell value, some controls may alarm, or no dwell will occur.

-

Too long P: Excess dwell may overheat the tool.

-

Forgetting G80: Always cancel the cycle when done.

-

Wrong plane: Stay in G17 for vertical drilling on VMCs.

Quick Checklist Before Running G82 Cycle

-

Tool & Spindle: Correct countersink/counterbore tool, spindle speed, direction (M3/M4), and coolant (M8).

-

Offsets: Ensure proper work offset (G54–G59) and tool length offset (G43 H__).

-

Cycle Parameters: Verify Z-depth, R-plane, and feedrate (F).

-

Dwell (P): Set appropriate dwell time (e.g., 300–500 ms for countersinking). Avoid too long a dwell.

-

Retract Mode: Choose G99 for fast retract to R-plane, G98 if clamps or obstacles are in the way.

-

Safety Check: Confirm clearance around fixtures and part features.

-

Cycle Cancel: Always end with G80 after drilling section.

-

Simulation: Perform a dry run or graphics simulation before actual machining.