When programming CNC machines, one of the most important parameters is cutting speed. It defines how fast the cutting edge of your tool moves across the workpiece surface. Getting this right ensures good tool life, smooth finishes, and efficient machining.

But here’s the catch: some machinists work in Imperial units (SFM – Surface Feet per Minute), while others use Metric units (m/min – meters per minute). In this post, we’ll explain both systems, show the formulas, and give you quick examples.

1. What is Cutting Speed?

Cutting speed (Vc) is the surface speed of the tool in contact with the workpiece. It depends on:

-

Tool diameter

-

Spindle speed (RPM)

-

Material being cut

2. Cutting Speed Formulas

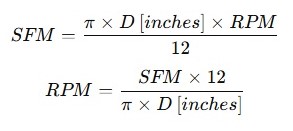

Imperial (SFM – Surface Feet per Minute)

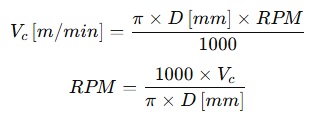

Metric (m/min – Meters per Minute)

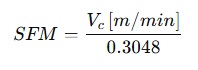

3. Conversions Between SFM and m/min

-

1 SFM = 0.3048 m/min

-

m/min → SFM:

4. Worked Examples

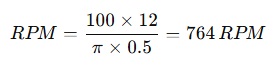

Example A – Milling in Imperial

End mill: 0.5″ diameter, cutting mild steel at 100 SFM.

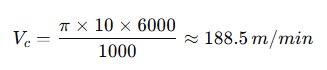

Example B – Milling in Metric

End mill: 10 mm diameter, spindle speed 6000 RPM.

Example C – Conversion

350 SFM × 0.3048 = 106.7 m/min.

5. Typical Cutting Speeds

| Material | Carbide (m/min) | Carbide (SFM) |

|---|---|---|

| Aluminum | 200–600 | 650–2000 |

| Mild Steel (1018) | 120–220 | 400–720 |

| Alloy Steel (4140) | 80–160 | 260–525 |

| Stainless (304) | 60–140 | 200–460 |

| Brass/Bronze | 200–400 | 650–1300 |

| Plastics | 100–300 | 325–980 |

(For HSS tools, reduce values to ~20–30% of carbide recommendations.)

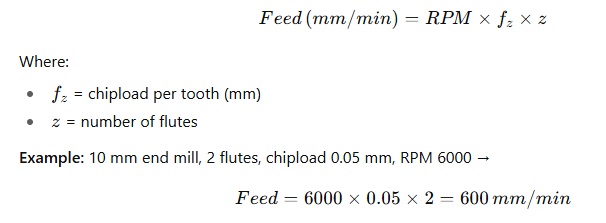

6. From Cutting Speed to Feed Rate

Once you have RPM, you can calculate feed:

7. Key Takeaways

-

SFM is used mainly in the US; m/min is the standard metric system.

-

Both are just two ways of expressing the same concept: cutting speed.

-

Always start with manufacturer recommendations, then fine-tune during test cuts.

-

Conversions are simple: 1 SFM = 0.3048 m/min.

By understanding both systems, you can work confidently with any tool data, calculator, or CNC machine manual—no matter where it comes from.