CNC machines are the backbone of modern manufacturing, and at the heart of every CNC machine lies the CNC controller. It acts as the brain, interpreting G-code and converting it into precise motions of machine tools. Choosing the right controller is crucial for accuracy, productivity, and ease of use.

In this blog, we’ll explore the most widely used CNC controllers in the industry, their strengths, and which applications they fit best.

Fanuc CNC Controllers

Fanuc, from Japan, is the global leader in CNC control systems. Known for its reliability and wide adoption, Fanuc controllers are found in lathes, mills, and EDM machines worldwide.

-

Strengths: Reliability, macro programming, global support.

-

Weakness: Traditional interface, requires training.

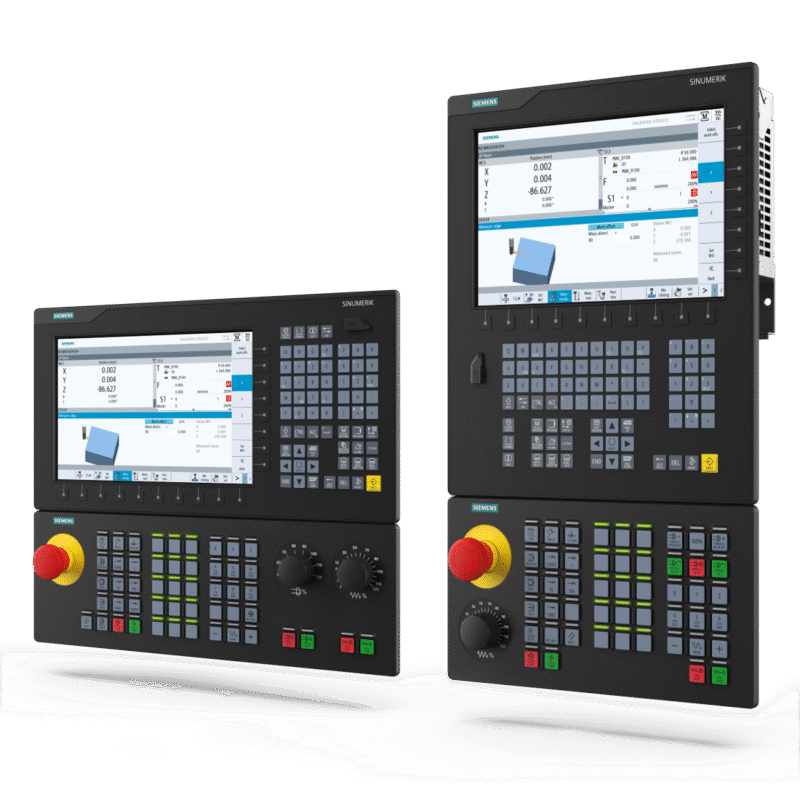

Siemens SINUMERIK Controllers

Siemens controllers are highly advanced and widely used in Europe for 5-axis machining and automation-heavy setups.

-

Strengths: Powerful, advanced simulation, integration with PLC.

-

Weakness: Expensive, steeper learning curve.

Mitsubishi CNC Controllers

Mitsubishi controllers (M70, M80, M800) are known for high-speed machining and smooth finishes.

-

Strengths: Compact, fast, great for milling and turning.

-

Weakness: Less popular outside Asia.

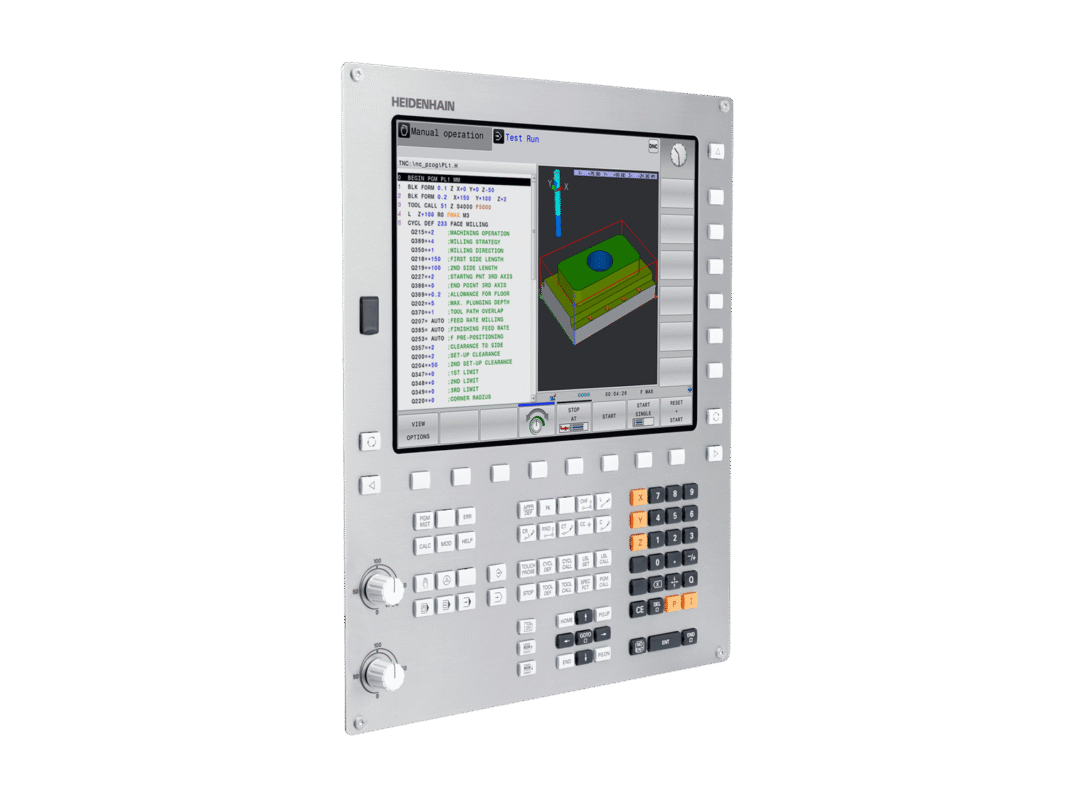

Heidenhain Controllers

German-made Heidenhain controllers (TNC series) excel in toolroom and die-mold machining, offering conversational programming and excellent accuracy.

-

Strengths: Easy to use, high accuracy.

-

Weakness: Limited in turning applications.

Okuma OSP Controllers

Okuma develops its own controller, the OSP series, tightly integrated with its machines.

-

Strengths: Stable, in-house hardware and software.

-

Weakness: Proprietary to Okuma.

Mazak Mazatrol Controllers

Mazak’s Smooth series controllers are conversational and AI-powered, designed for ease of programming and multi-tasking machines.

-

Strengths: Easy programming, advanced features.

-

Weakness: Proprietary to Mazak.

Haas CNC Control

Haas offers one of the most user-friendly CNC controls in the industry, ideal for training centers and small job shops.

-

Strengths: Simple, affordable, modern interface.

-

Weakness: Not as advanced for high-end aerospace or die-mold work.

Fagor Automation Controllers

Fagor (Spain) is popular in Europe, offering a balance of conversational and G-code programming.

-

Strengths: Good diagnostics, milling & grinding focus.

-

Weakness: Less common globally.

Hurco WinMax Controllers

Hurco’s WinMax control is designed for ease of use with strong conversational programming features.

-

Strengths: Beginner-friendly, ideal for toolrooms.

-

Weakness: Less suited for large-scale production.

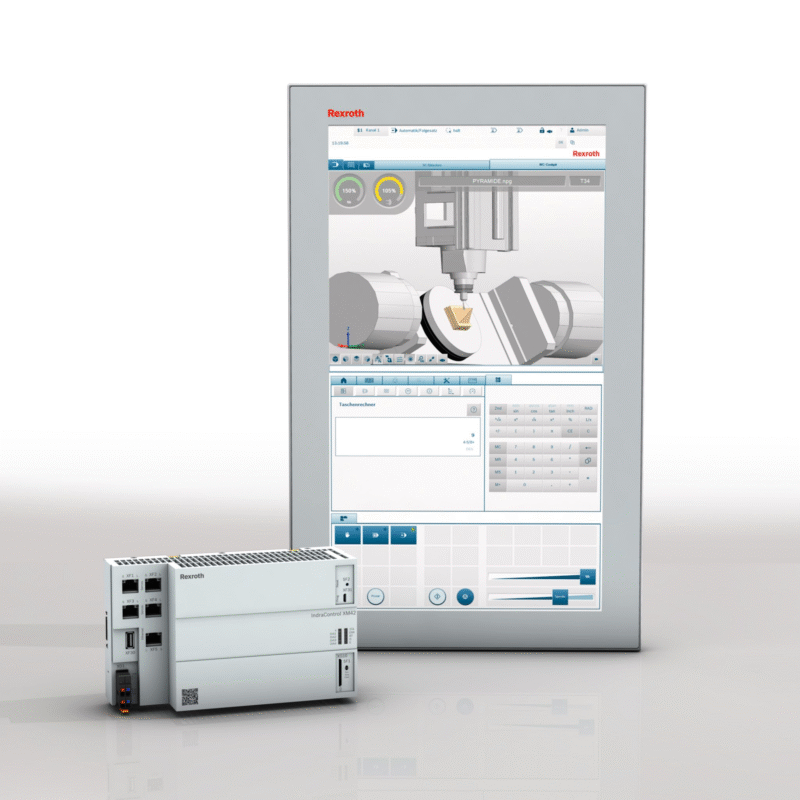

Bosch Rexroth MTX Controllers

Bosch Rexroth CNC controllers are built for automation-heavy industries, especially automotive and aerospace.

-

Strengths: Multi-axis integration, strong in automation.

-

Weakness: Expensive, complex setup.

Conclusion

Each CNC controller has its own strengths and is tailored for specific industries.

-

Fanuc & Siemens → Global leaders, ideal for high-production environments.

-

Heidenhain & Hurco → Perfect for toolrooms and die-mold machining.

-

Haas → Affordable and beginner-friendly for job shops.

-

Mazak & Okuma → Proprietary but highly optimized for their machines.

The right controller depends on your machine type, budget, and production requirements.