In CNC machining, accuracy depends on more than just the program code – it also relies on how the machine understands tool dimensions. On a Vertical Machining Center (VMC), the concepts of Tool Length Offset (TLO) and Tool Diameter (Radius) Offset (TDO) are crucial.

Author Archives: dinesh11580@gmail.com

One of the most important concepts in CNC programming is the Work Coordinate System (WCS). It defines the reference point from which all machining operations are programmed. Without a proper understanding of WCS, even the most accurate CNC program can produce errors or crash the machine.

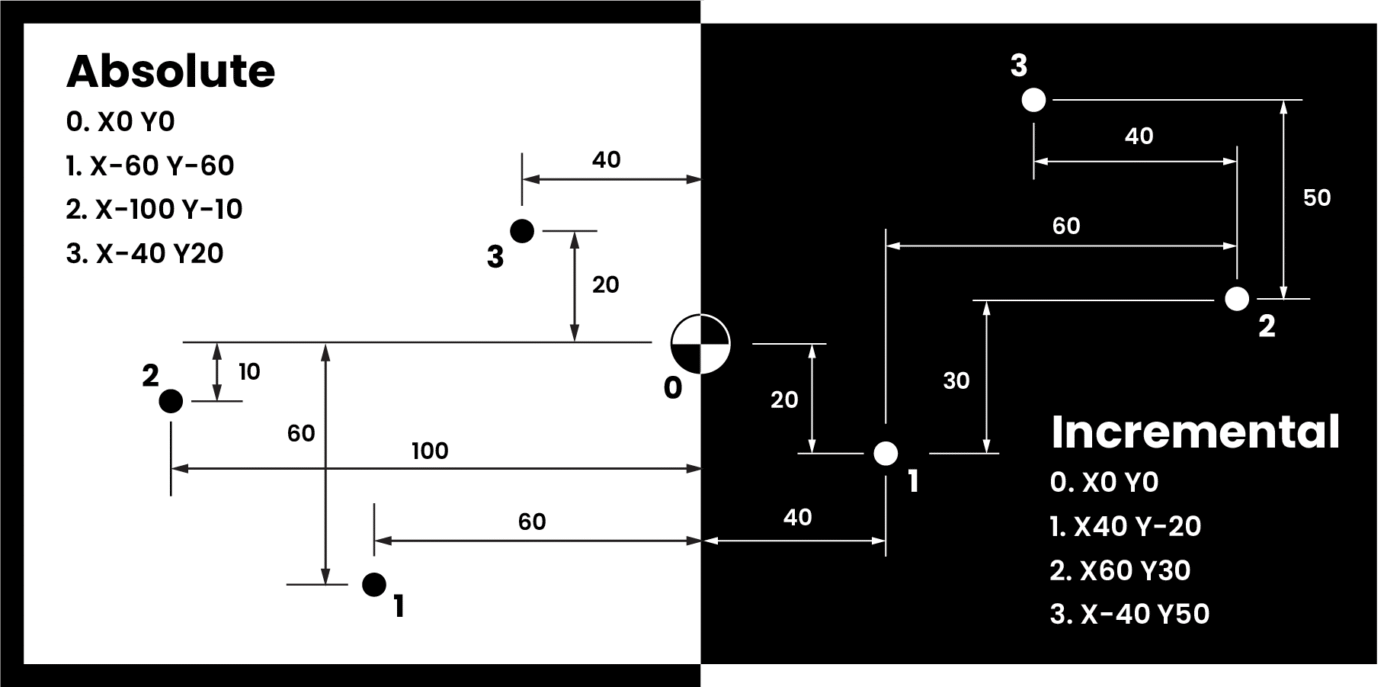

When it comes to CNC programming, two essential coordinate systems define how a machine interprets tool movement: Absolute Programming (G90) and Incremental Programming (G91). Understanding the difference between the two is crucial for CNC programmers, as it directly affects accuracy, efficiency, and error prevention.

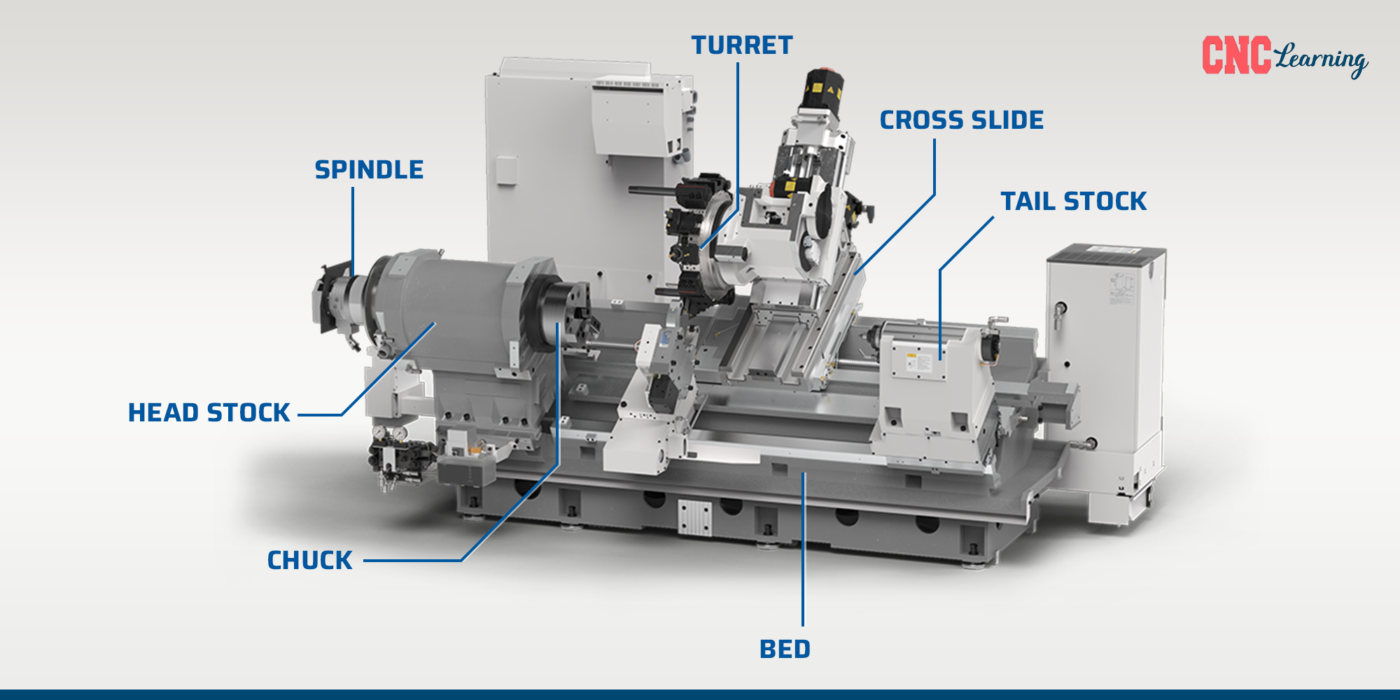

Turning centers are essential machines in modern manufacturing, known for their ability to perform turning operations with high precision and efficiency. Understanding the main parts of a turning center can help CNC operators and engineers appreciate the machine’s structure and functionality. Here’s a breakdown of the key components and their roles in the operation of a turning center.

Vertical Machining Centers (VMCs) are precision-driven machines designed for efficient and versatile manufacturing processes. Understanding the main parts of a VMC machine is essential for operators, programmers, and maintenance teams. Here’s a comprehensive guide to the key components of a VMC machine.

CNC (Computer Numerical Control) machines have revolutionized the manufacturing industry by offering precision, automation, and versatility. These machines are categorized based on their functionality, axis configuration, and application. Below is a comprehensive classification of CNC machines to help you understand their diversity and capabilities. 1. Classification by Machine Type CNC Milling Machines CNC Lathes CNC […]

CNC (Computer Numerical Control) machines have revolutionized manufacturing by introducing precision, automation, and efficiency into machining processes. Understanding the history of CNC machines provides insight into how they evolved and transformed industries worldwide.

What is G10 in Fanuc CNC?G10 is a powerful G-code in Fanuc CNC programming that allows machinists to programmatically set various parameters, such as work offsets, tool data, and other machine settings. This capability eliminates the need for manual input into the machine’s control system, enhancing efficiency and reducing errors. How G10 Works The G10 […]

- 1

- 2