In CNC machining with Fanuc controllers, the M198 code is a powerful feature that allows you to call and execute a subprogram stored on external memory (such as a memory card, data server, or USB device). Unlike the regular M98 subprogram call, which looks inside the machine’s control memory, M198 looks at the external storage and runs the program directly from there.

When programming CNC machines, one of the most important parameters is cutting speed. It defines how fast the cutting edge of your tool moves across the workpiece surface. Getting this right ensures good tool life, smooth finishes, and efficient machining.

Mastering feeds and speeds isn’t complicated—it’s about understanding the formulas, starting with recommended values, and then adjusting for your specific setup. By applying the steps in this guide, you’ll extend tool life, achieve smoother finishes, and cut more efficiently.

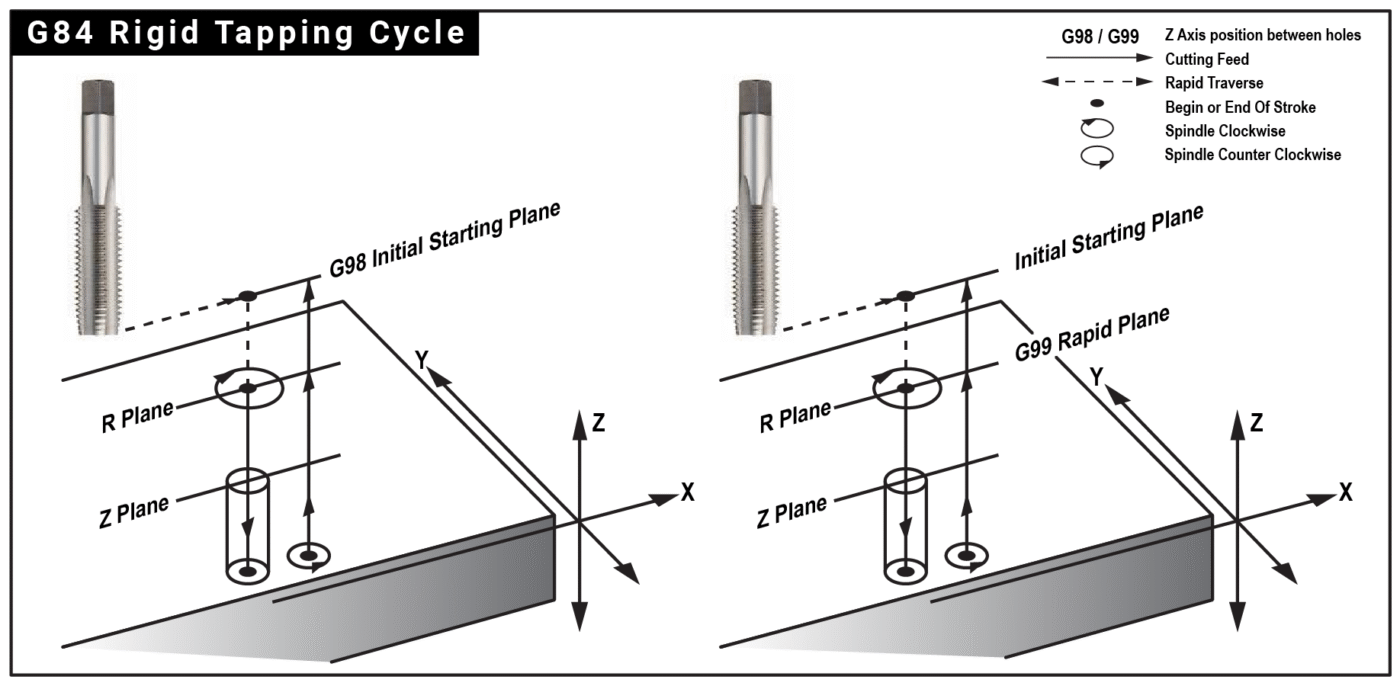

The G84 canned cycle is primarily used for tapping threads inside drilled holes. Unlike drilling cycles such as G81, G82, and G83, tapping requires precise synchronization between the spindle and feed with the thread pitch. Therefore, the G84 cycle automatically controls both spindle rotation and feed, so that the tap cuts correctly and, as a result, reduces the risk of tool breakage. In addition, this automation makes the tapping process faster and more reliable compared to manual programming

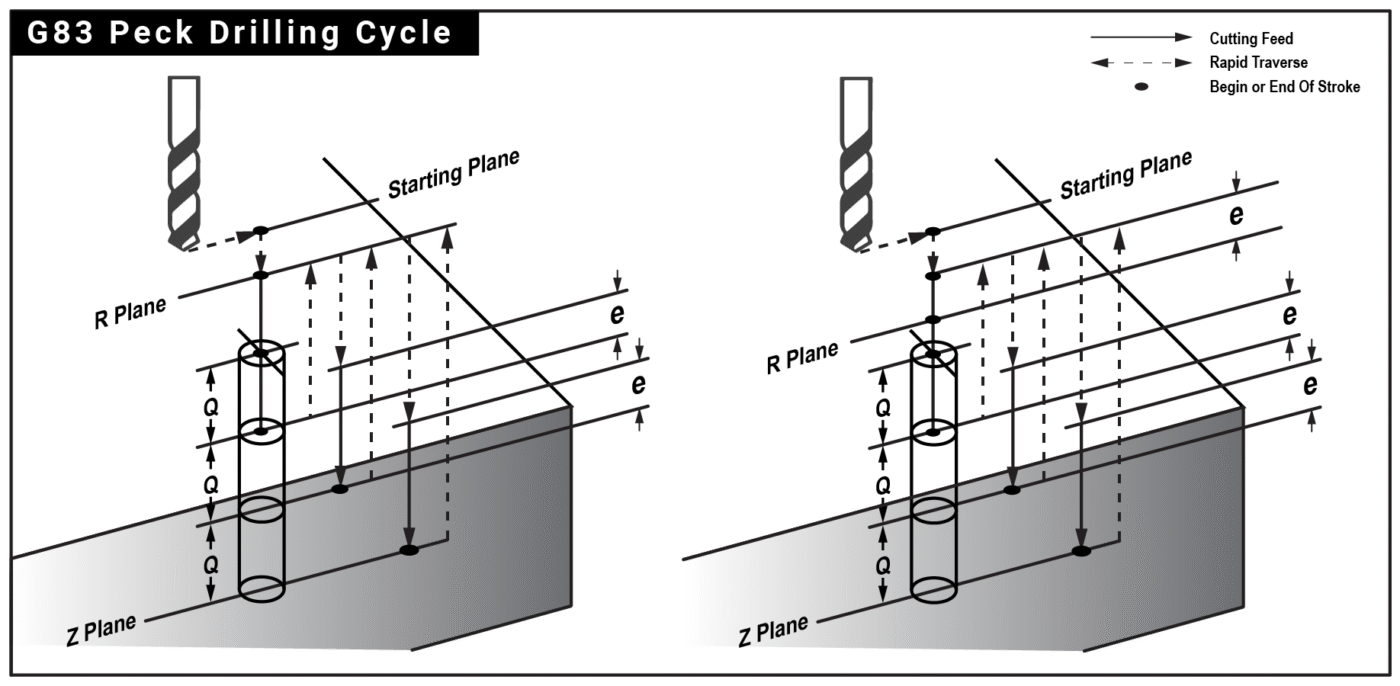

The G83 canned cycle is used for deep hole drilling where chips must be cleared in steps (pecks) to prevent tool breakage. Unlike G81 (simple drilling) and G82 (drilling with dwell), G83 drills in repeated pecks, retracts slightly to break and clear chips, and then continues until the final depth is reached.

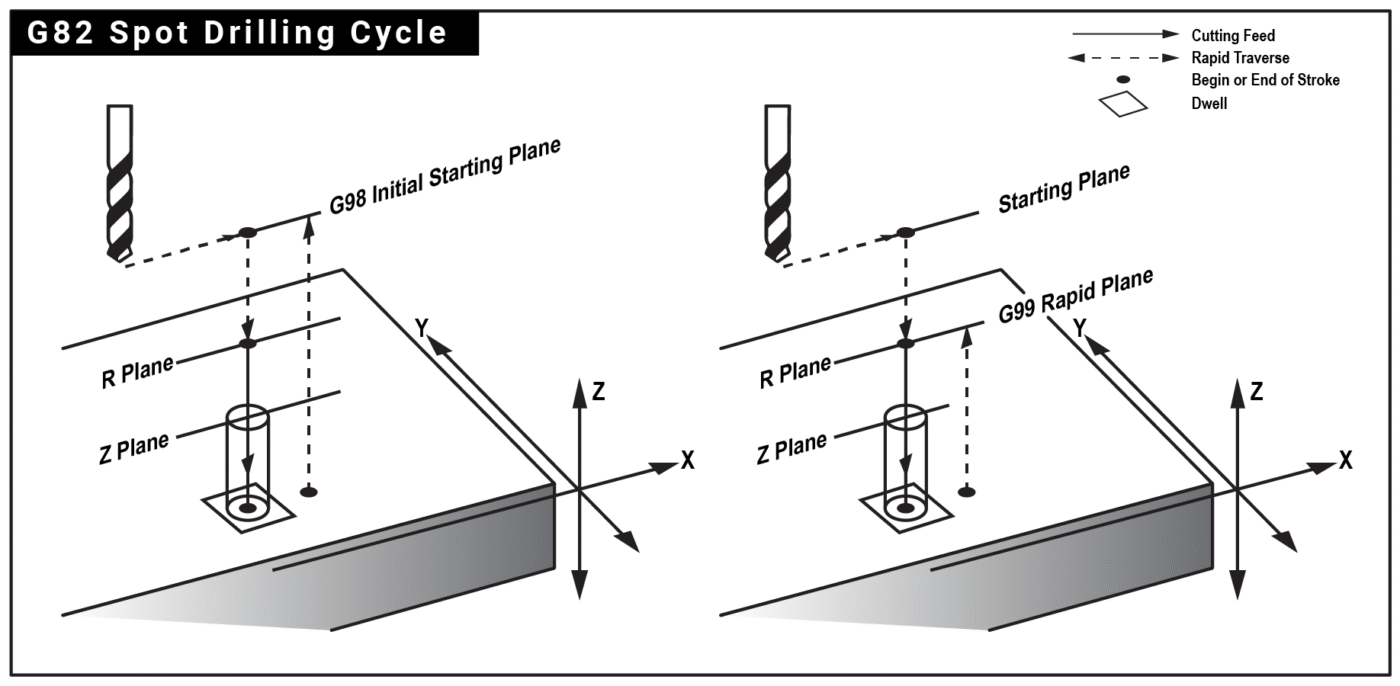

G82 is a drilling cycle similar to G81, but with an added dwell time at the bottom of the hole. After feeding down to the programmed depth (Z), the tool pauses for the specified time (P value) before retracting. This dwell improves hole accuracy, helps create a cleaner bottom surface, and is commonly used for countersinking and counterboring operations.

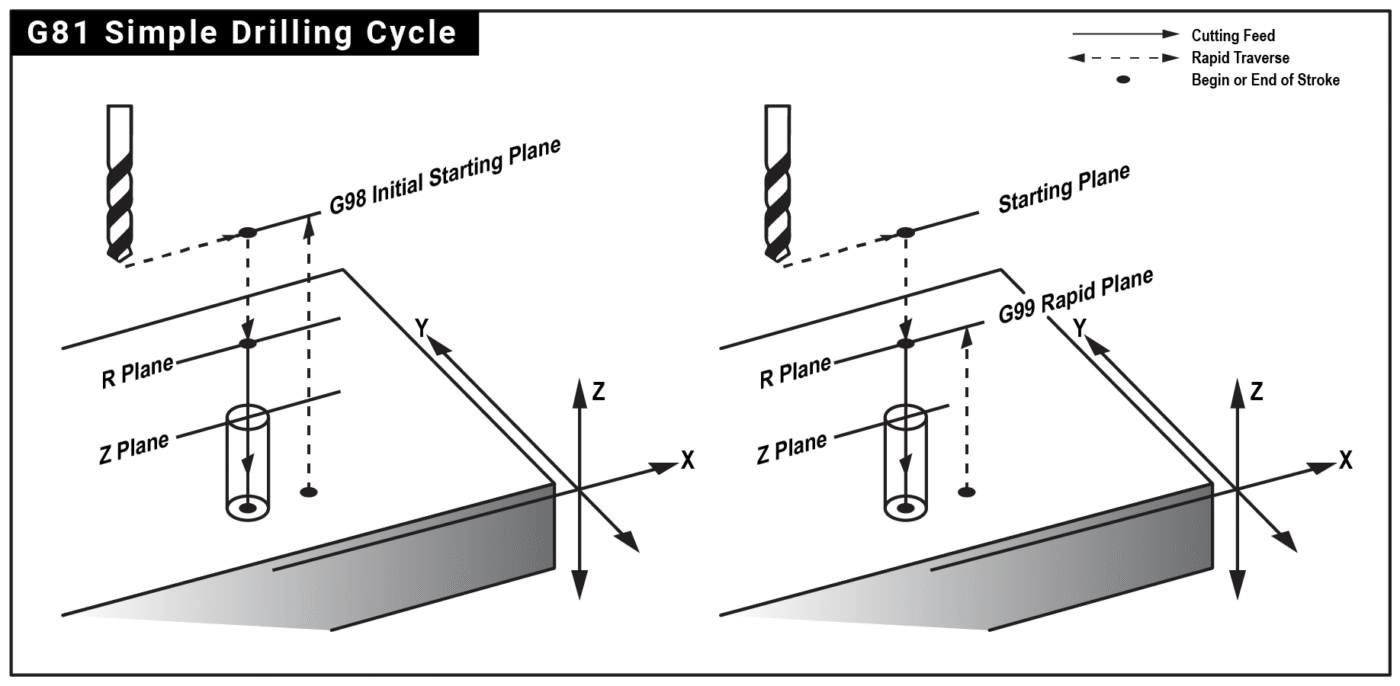

G81 is the simplest drilling canned cycle. It rapids to a safe clearance plane (R), feeds straight to the programmed depth (Z), and retracts—either back to the R-plane (G99) or all the way to the initial plane (G98). Use it for shallow to moderate depth holes where you do not need pecking or a dwell.

The G80 command in Fanuc CNC programming is used to cancel any active drilling, boring, or tapping canned cycle (such as G81, G82, G83, G84, etc.). Once a canned cycle is active, it will keep repeating at every new X-Y coordinate until it is explicitly stopped. If not canceled, the cycle may unintentionally continue at the wrong positions, causing tool crashes or part damage.

When programming a Vertical Machining Center (VMC), certain operations like drilling, boring, tapping, and reaming are repetitive. Writing full toolpath codes (G01, G00, G02, G03) for each step would be time-consuming.

To simplify this, Fanuc controls (and most CNC controls) use Canned Cycles – pre-programmed subroutines that perform common machining operations with just one command line.

- 1

- 2