The G80 command in Fanuc CNC programming is used to cancel any active drilling, boring, or tapping canned cycle (such as G81, G82, G83, G84, etc.). Once a canned cycle is active, it will keep repeating at every new X-Y coordinate until it is explicitly stopped. If not canceled, the cycle may unintentionally continue at the wrong positions, causing tool crashes or part damage.

Function:

-

Stops the active canned cycle.

-

Returns machine control to normal single-line G-code commands.

-

Prevents unintended hole machining at subsequent coordinates.

Format:

G80

Example:

N10 T1 M6

N20 G90 G54 G0 X20 Y30 S1200 M3

N30 G43 Z100 H01

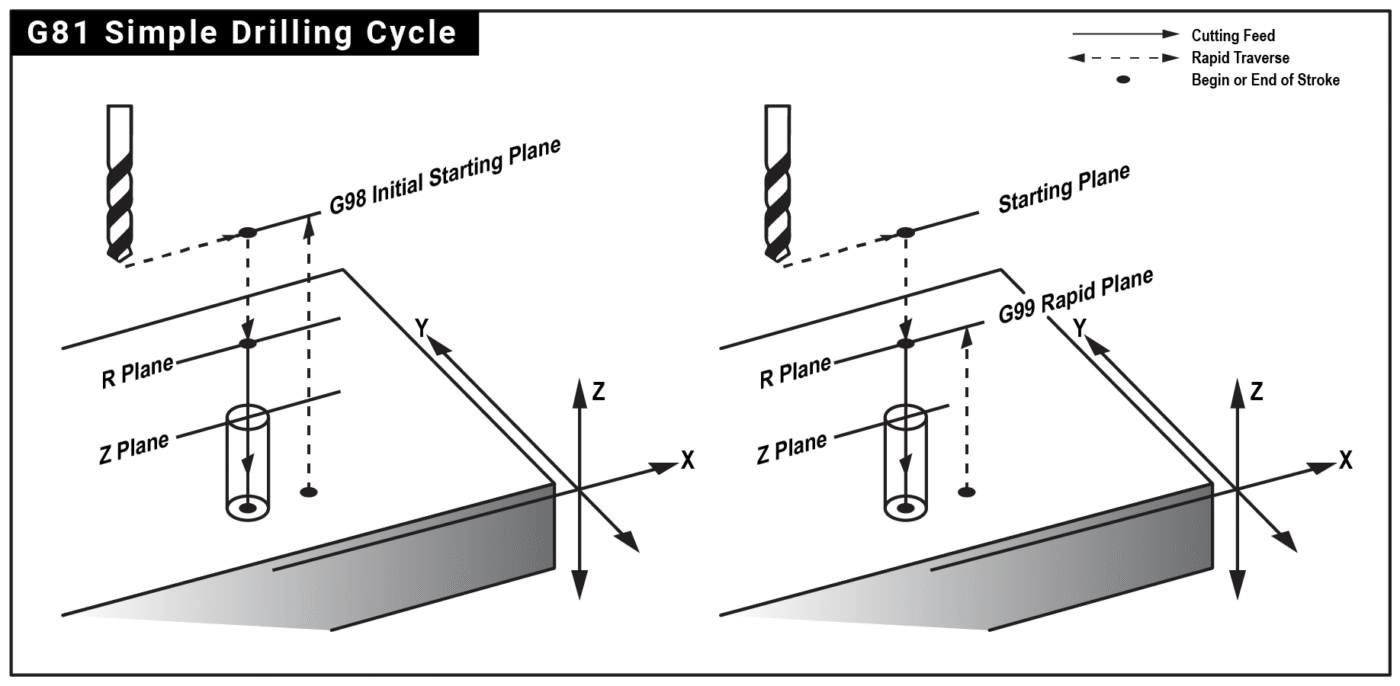

N40 G81 G99 X20 Y30 Z-20 R2 F100

N50 X40 Y30

N60 X60 Y30

N70 G80 (Canned cycle cancelled here)

N80 G0 Z100 M5

N90 M30

In this example, G81 is used to drill three holes. After that, G80 cancels the drilling cycle before moving the tool away.

Key Points to Remember:

-

Always use G80 after completing drilling or tapping cycles to ensure safe programming practice.

-

If you forget to cancel, the machine may try to drill or tap at unintended locations.

-

G80 is a modal command – once active, it remains until another cycle (G81–G89) is programmed.

In short: G80 is the “safety brake” for canned cycles in VMC programming – it cancels the cycle and returns control to standard G-code execution.