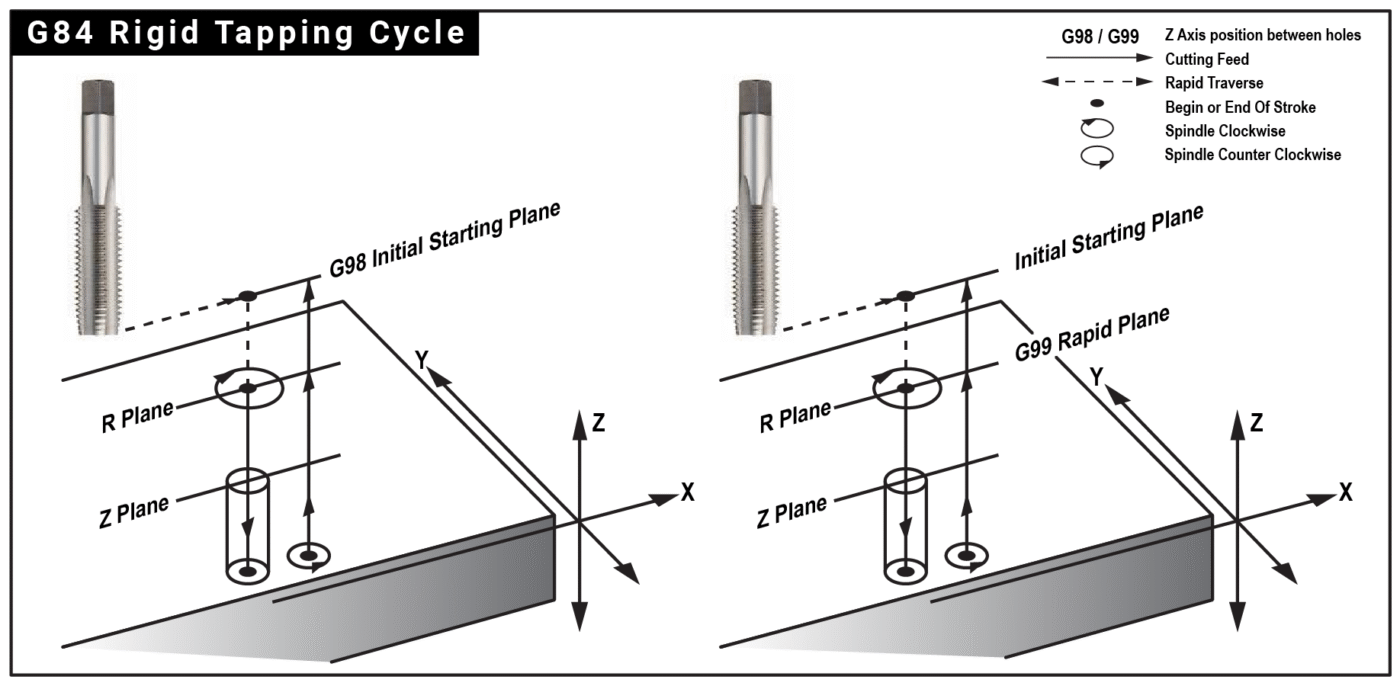

The G84 canned cycle is primarily used for tapping threads inside drilled holes. Unlike drilling cycles such as G81, G82, and G83, tapping requires precise synchronization between the spindle and feed with the thread pitch. Therefore, the G84 cycle automatically controls both spindle rotation and feed, so that the tap cuts correctly and, as a result, reduces the risk of tool breakage. In addition, this automation makes the tapping process faster and more reliable compared to manual programming

Tag Archives: canned cycle

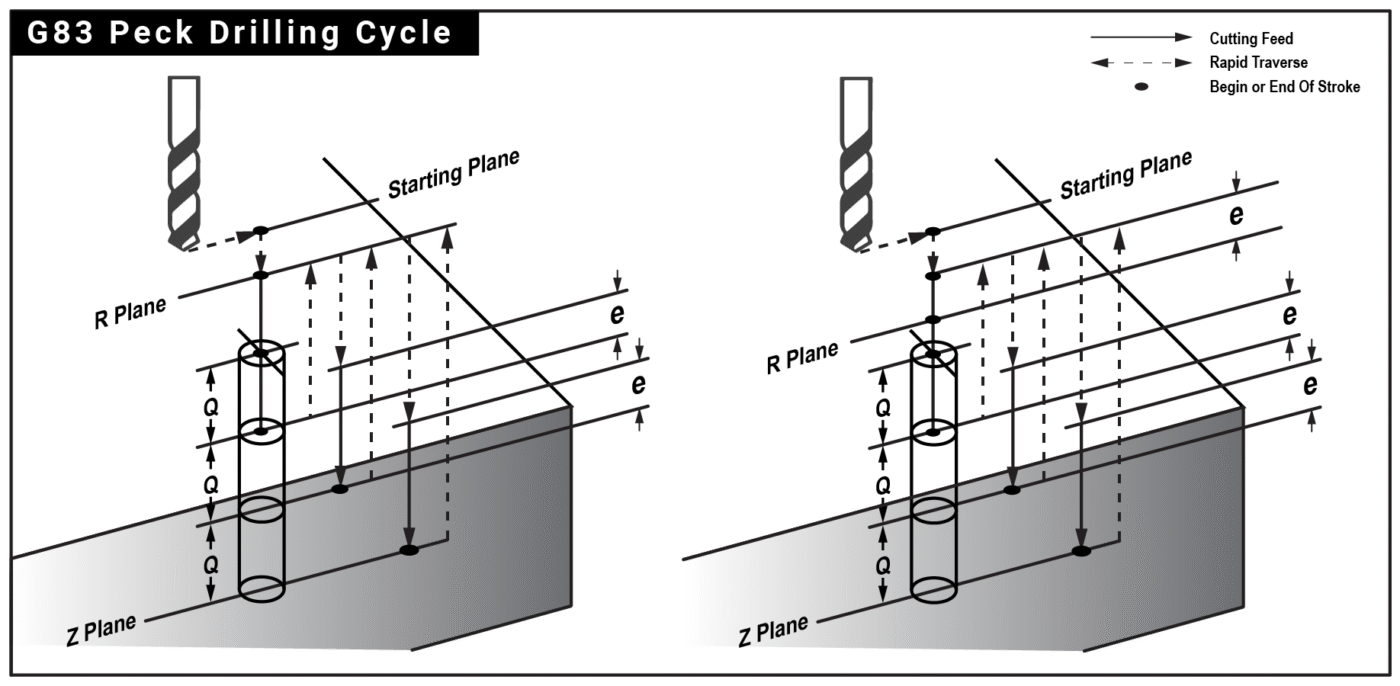

The G83 canned cycle is used for deep hole drilling where chips must be cleared in steps (pecks) to prevent tool breakage. Unlike G81 (simple drilling) and G82 (drilling with dwell), G83 drills in repeated pecks, retracts slightly to break and clear chips, and then continues until the final depth is reached.

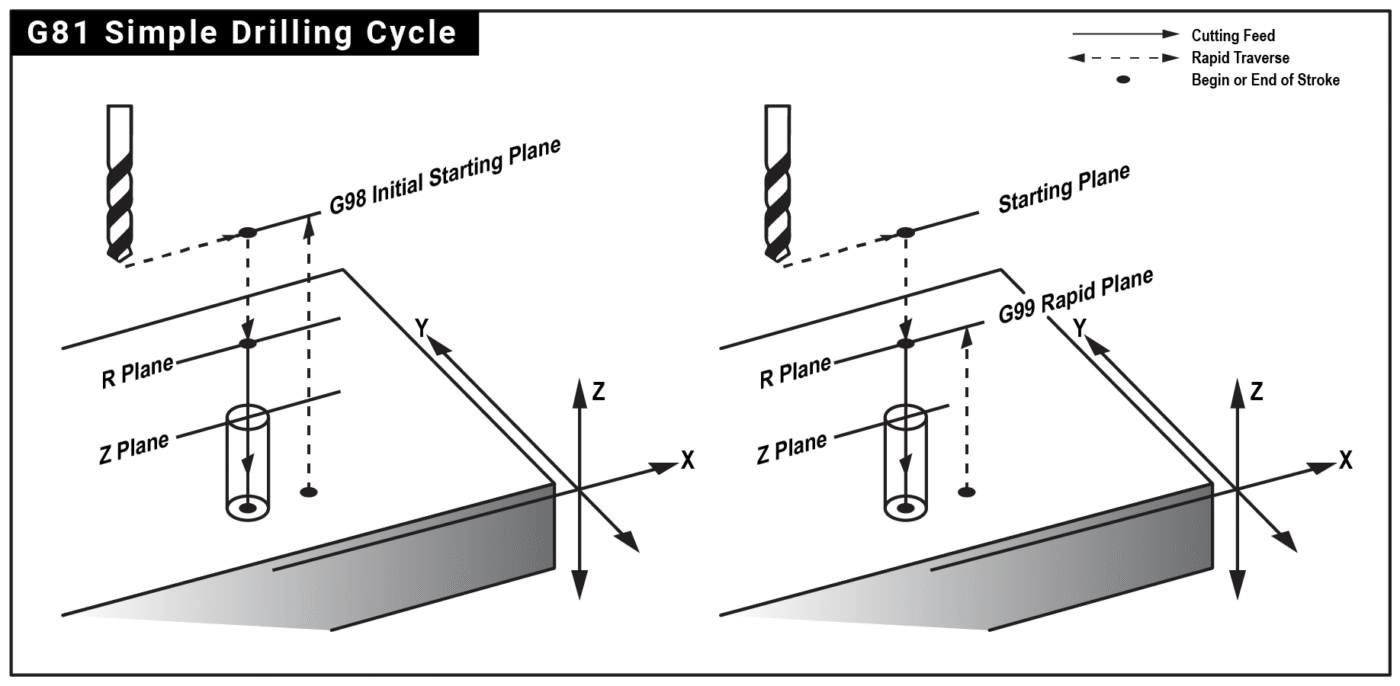

G81 is the simplest drilling canned cycle. It rapids to a safe clearance plane (R), feeds straight to the programmed depth (Z), and retracts—either back to the R-plane (G99) or all the way to the initial plane (G98). Use it for shallow to moderate depth holes where you do not need pecking or a dwell.